Cameron Automation

For over 20 years, Cameron Automation, a division of Taylor Mfg, has been building high-tech machinery for automating and improving rough mill processes. Cameron Automation's efficient and productive mechanical designs, coupled with sophisticated and powerful software, increases raw material utilization - all backed by industry-leading customer service from highly trained technicians.

Skew - Full rip optimization system for the custom shop

- Improve safety by removing the operator from the kick-back danger zone

- Lumber savings by increasing yields 7-10% over hand feeding

- Machine pays for itself ripping 1500 board feet per day

- Improved data collection with fully integrated rip software

The Quick Rip is a complete Rip Saw Automation Infeed in a simple and compact package, 15,000 - 17,000 board feet per shift

- Innovative fenceless design with auto-skewing of non-straight boards

- Features 2, 3, and 4 moving blade rip saws

- Auto-Skew feature improves yields 2-3% over the competition

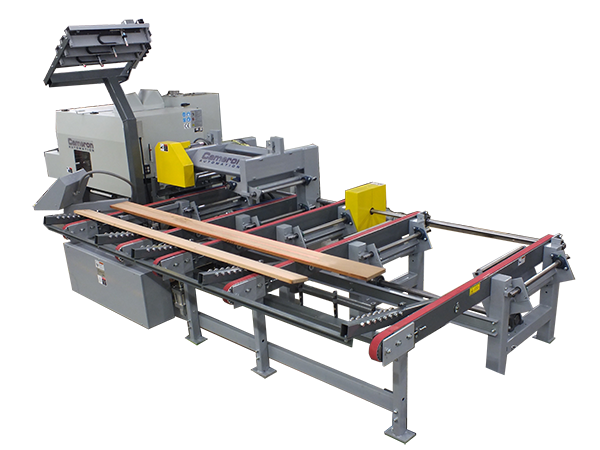

The Cameron Automation Rip-One is a complete lumber scanning, optimization, and gang ripping work cell designed for smaller shops

- It increases productivity dramatically by transforming gang ripping into a single person operation. This is achieved by incorporating an inexpensive but extremely powerful high-resolution 3D scanning system.

The Quick Chop is an affordable push feed chop saw optimization system

- Crayon marking for defects

- Accuracy as low as +/-0.010 in.

- Full chop optimizing software with cut list importing capabilities and production tallying

- Multiple grades and grade sharing capabilities to improve yield

- Normal production is 3,000-12,000 lineal feet per shift

- Several outfeed systems / sorting belts available

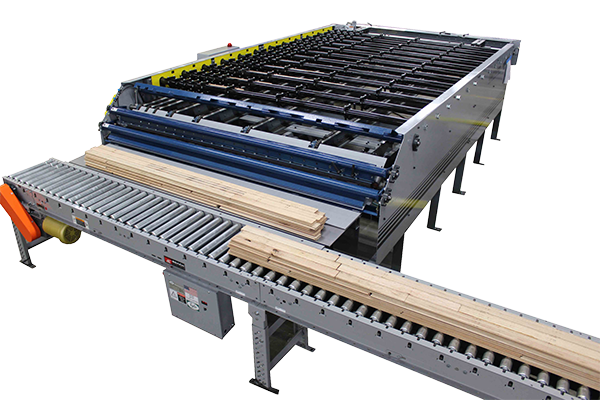

Flooring Nester - Random flooring strips are fed in one end and nested bundles are produced at the other end

- Produces better bundles with higher yield (2.5% on every bundle)

- Eliminates repetitive manual labor

- Controls square footage in each bundle

- Tallies material automatically