James L. Taylor Manufacturing Company

Engineered, manufactured, and serviced from our 100,000 sq. ft. facility in Poughkeepsie, NY by a dedicated team of smart and skilled professionals, the James L Taylor Manufacturing Company provides industry leading innovations for edge gluing and lumber optimization technologies in a wide range of applications and markets.

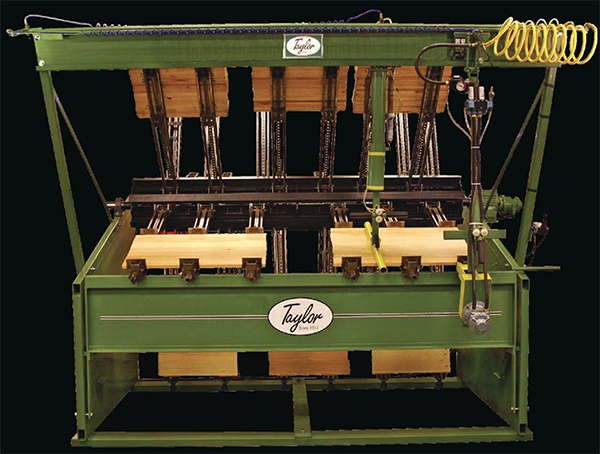

Standard Clamp Carrier

- Custom cabinet door shop

- Smaller furniture manufacturer

- Simple pneumatic operation

- 75-100 panels per day depending on size

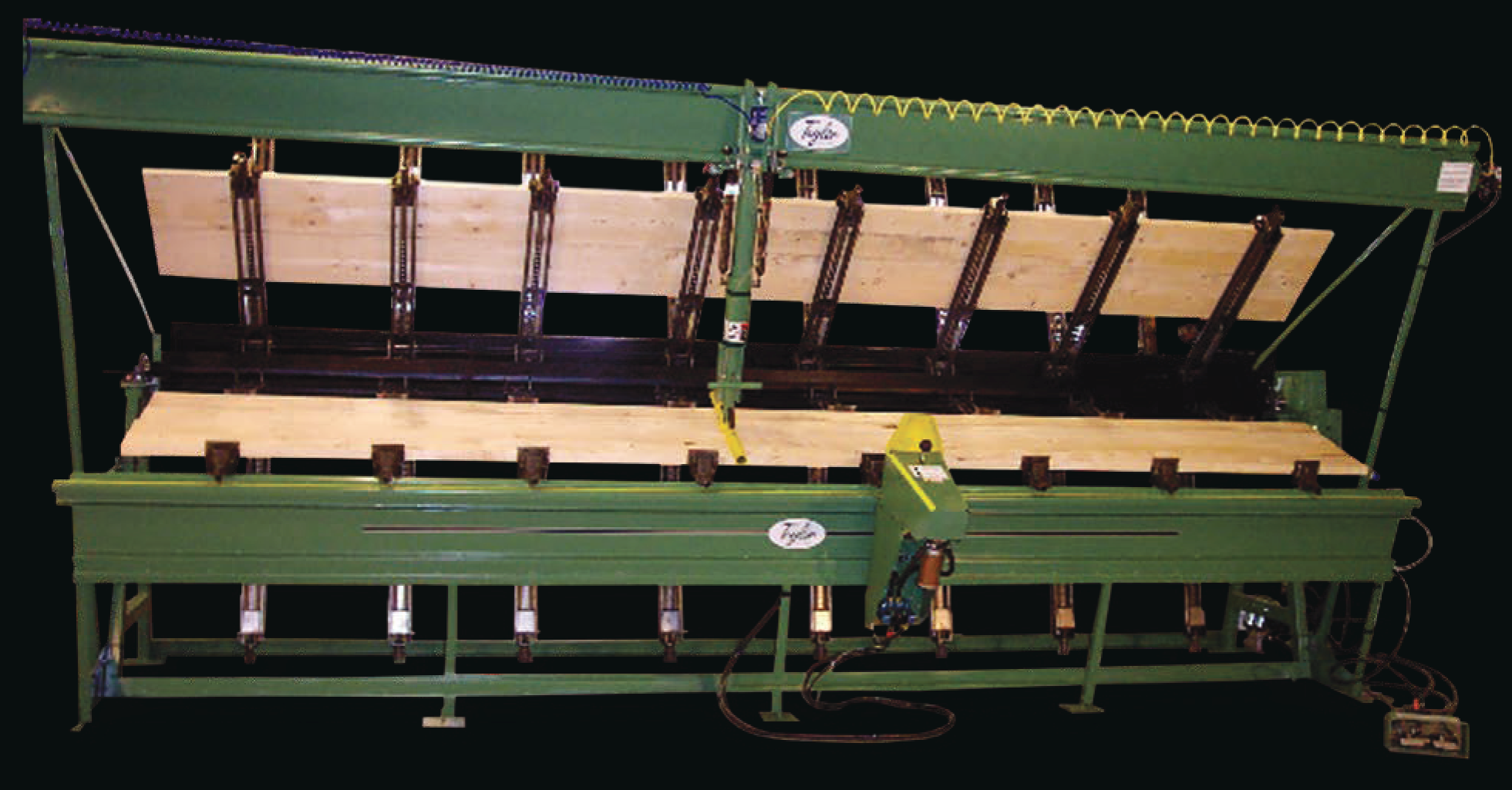

Semi-Auto Clamp Carrier

- Custom stair components

- Architectural moulding and millwork

- Available in pneumatic and hydraulic configurations

- Up to 20-1/2" panels or laminations

Automated Clamp Carrier

- Available in pneumatic and hydraulic configurations

- Automated operations

- Industry standard for high production

- Production up to 1000 panels per day depending on size

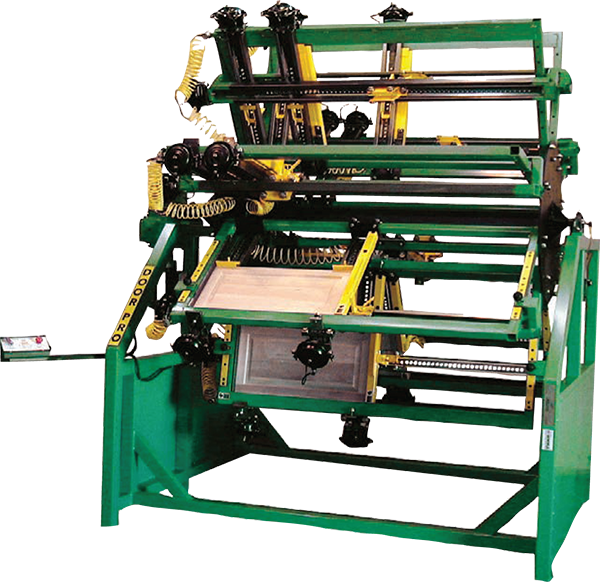

Taylor Door Pro

- Cabinet Doors: Mitered and/or Stile & Rail

- 5 & 8 section machines available

- 3 squaring sizes available

- Production up to 350 door per day

- No need for pinning

Taylor Return Conveyor

- Models for edgebanders, straight line rip saws, and wide belt sanders

- Three standard models for material from 78" to 132" long

- 24" or 36" rollers on return conveyors can handle up to 36" or 50" wide material

- Any length return section composed of modular sections

Glue Applicators

We have three models to choose from

- The Plate Spreader: Simple and durable

- The Roller Spreader: A simple roller spreader with precise glue spread

- The Conveyorized Glue Applicator: High production, high quality spreader